which of the following is a type of machine safeguarding osha 10

One or more methods of machine guarding shall be provided to protect the operator and other employees in the machine area from hazards such as those created by point of operation ingoing nip points rotating parts flying chips and sparks. Connecting the machine to an energy source Question 1.

Administrative Assistant Resume Sample Administrative Assistant Resume Resume Skills Resume Objective Examples

4 Occupational Safety and Health Administration List of Tables Table 1.

. C Poinit of operation. Protective measures consisting of the use of specific technical means called safeguards guards protective-devices to protect workers from hazards that cannot be reasonably removed or sufficiently limited by design. Good to operate.

Keeping this in consideration what are the most common types of machine guarding. Additionally there are plenty of instances where OSHA requires or recommends secondary controls such as alarms and fences. OSHA Quizzes 92 Terms.

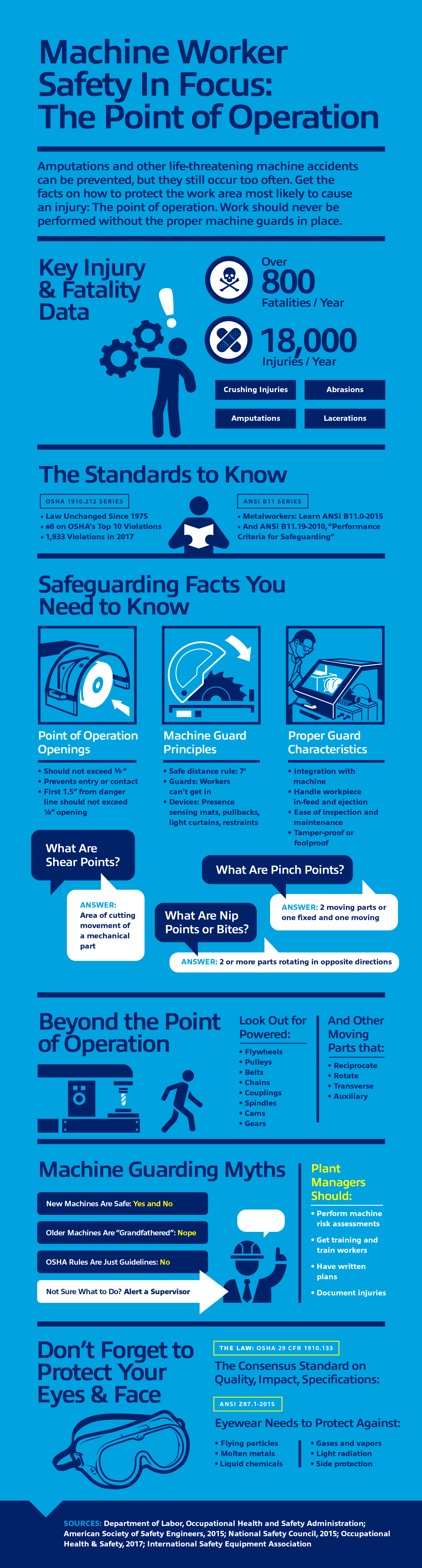

Primary Safeguarding Methods Two primary methods are used to. Wrists are connected by cords and secured to a fixed anchor point which limit operators hands from reaching the point of operation at any time. Machine guards are your first line of defense.

Most usable machine guards are described below. A and B gate requirements. Must prevent workers from lubricating a machine without removing the safeguard.

_____ True or False. General Industry Machine Guarding v030117 20 Created by OTIEC Outreach Resources Workgroup Machinery That Requires Guarding Machines that require point of operation guarding. The A gate is used in both full and part revolution clutch presses while the B gate is for part revolution presses only.

Machine safeguarding helps protect workers from preventable injuries in all three areas. B Feeding and Ejection methods. Guillotine cutters Shears Alligator shears Power presses Milling machines Power saws Jointers Portable power tools Forming rolls and calenders Source.

Types of Safeguarding Devices 13. OSHA Safety and Health Information Bulletin SHIB January 25 2013. Probe detection and safety edge devices.

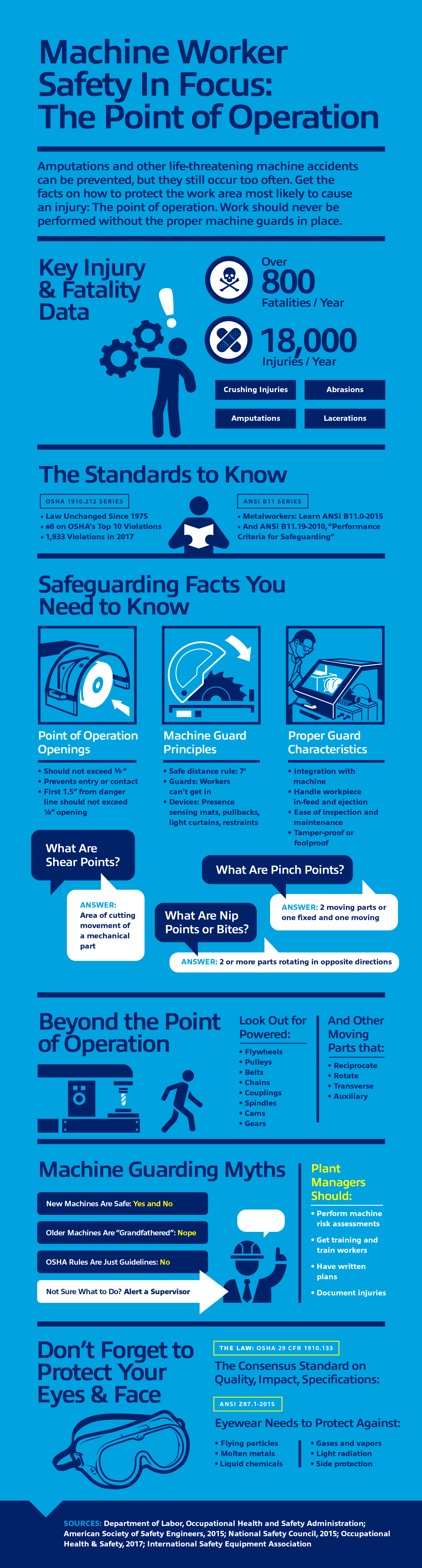

The safeguarding general rule to prevent hazards during servicing or maintenance of machines including all of the following except. Interlock into the machines control system to stop operation when the sensing field photoelectric radio frequency or electromagnetic is disturbed. Moving machine parts have the potential to cause severe workplace injuries such as crushed fingers or hands amputations burns or blindness.

Also Know what are the 2 types of primary safeguarding methods. Various types of machine guards available for machine guarding. Primary machine can fill in as.

Which of the following is a type of machine safeguard. Replace it at the end of the shi L. D In-going nip points.

The following are all machine safeguarding requirements except. 3 Fixed adjustable access guard. There seem to be as many hazards created by moving machine parts as there are types of machines.

Which of the following types of machine guard is generally preferred because of its simplicity and durability. Which of the following is a type of machine safeguarding. The following are all machine safeguarding requirements except.

Type A and B Gates are both recognized methods for power press safeguarding. Each piece of machinery has its own unique mechanical and non-mechanical hazards. Their suitability should be selected.

Machine guarding typically applies to the point of operationthat is the location on or near the machine where work is performed. Safeguards are essential for protecting workers from these preventable injuries. The following are all machine safeguarding requirements except.

CompTIA 220-701 250 Terms. This OSH Answers fact sheet is based. Examples of guarding methods are-barrier guards two-hand tripping devices electronic safety devices etc.

This problem has been solved. To ensure that employees are properly protected from machine hazards employers must assess the workplace and identify potential. The Occupational Safety and Health Administrations OSHAs requirements for machine guarding are found in 29 Code of Federal.

The CSA standard Z432 Safeguarding of machinery defines safeguarding as. When you are protected by the with you opera ng the machine safeguards and others in the work 1. If a new guard causes interference 4.

Safeguards are essential for protecting workers. The most common types of machine guards are. Must prevent workers from lubricating a machine without removing the safeguard.

2 Fixed limited access guards. There seem to be as many hazards created by moving machine parts as there are types of machines. Contents hide 1 Fixed guards.

Any part of a machine which ___ while in operation can cause a hazard. See the answer See the answer done loading. Moveable barrier that protects operator at point of operation before machine cycle can be started Must be interlocked so machine cannot begin cycle unless gate guard is in place Must be closed before machine can function Types A Gate.

Types of Machine Guarding Restraint Devices. Machines can cause a variety of injuries ranging from minor abrasions burns or cuts to severe injuries such as fractures lacerations crushing injuries or even amputation. All machines consist of three fundamental areas the point of operation the power transmission device and the operating controls.

Types of Machine Safeguards Gate devices. Secondary methods of guarding machines. The Basics of Machine Guarding Crushed hands and arms severed fingers blindness -- the list of possible machinery-related injuries is as long as it is horrifying.

Why OSHA Machine. Prevent or detect operator contact with the point of operation or stop potentially hazardous machine motion if any part of an individuals body is within the hazardous portion of the machine. An employee trained on his you can take it off as long as you area are protected also you are.

Any part of a machine which ___ while in operation can cause a hazard. However many machines need to be safeguarded at multiple points. Commonly Used Machine Guards 12 Table 2.

YOU MIGHT ALSO LIKE. Any machine part function or process that may cause injury must be.

Machine Guarding Named To Osha S Top Ten Violations List For 2021 The National Provisioner

Machine Guard Infographic The Point Of Operation Better Mro

Administrative Assistant Resume Sample Administrative Assistant Resume Resume Skills Resume Objective Examples

Osha 2045 Machinery And Machine Guarding Standards Chesapeake Region Safety Council

What Is Machine Safeguarding T P Supply Co

Crane Balancing Act Truck Cranes Crane Construction

Osha Office Of Training And Education 1 Machine Guarding Ppt Download

10 Safety Tips For Osha Standards Industrial Safety Industrial Safety Osha Safety Training Health And Safety Poster

Oshacademy Course 154 Machine Safeguarding Basic Module 2

Williams 12 X 3 4 Drive Impact Extension 6 113 In 2022 Schuylkill County Driving Valley View

Free Whitepaper Evaluating Fire Damaged Regulators How Reliable Is Post Fire Testing Fire Damage Water Damage Repair Damage Restoration

Poll Radial Arm Saws The Wood Whisperer Radial Arm Saw Saws Radial Saw